Well, the reality is far more fascinating than you might think. Let’s dive deep into how this cutting-edge technology works and why it’s revolutionizing metal fabrication.

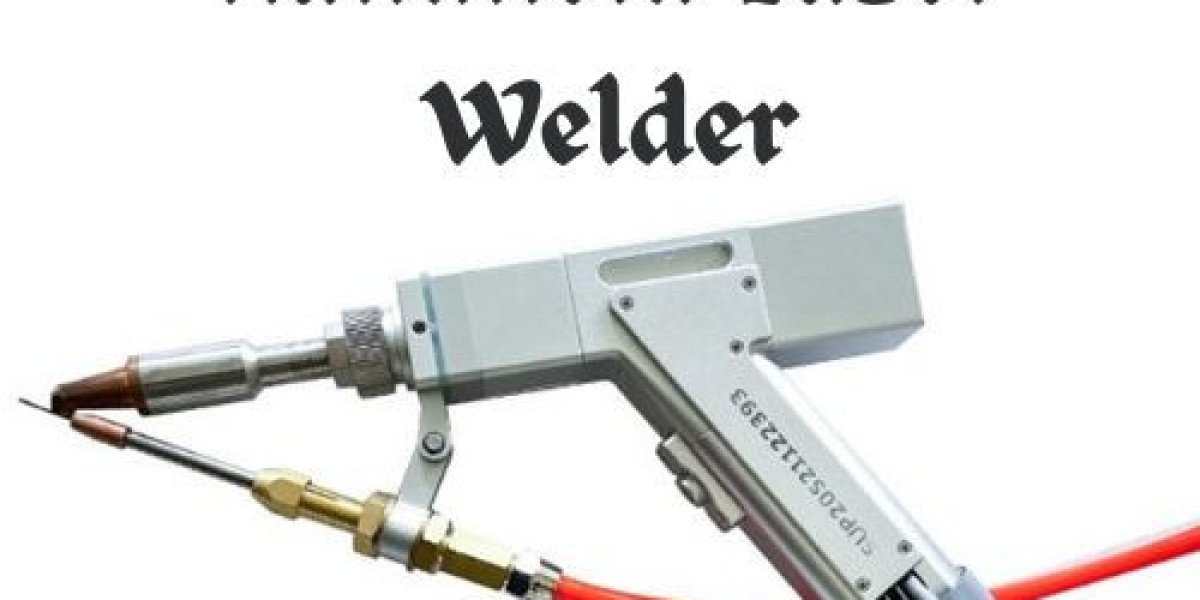

How Does a Handheld Laser Welder Work?

A handheld laser welder uses a highly focused laser beam to generate extreme heat at a precise point, allowing it to fuse metals together. But here’s the twist—it doesn’t always require melting the entire workpiece. Instead, it can create a metallurgical bond through a process called conduction welding, where only the surface layers are softened enough to merge without full liquefaction.

This method is different from traditional welding, where the base metal must melt completely to form a pool of molten material. With a handheld laser welder, the energy is so concentrated that it can achieve a strong weld with minimal heat input, reducing distortion and preserving material properties.

The Science Behind Laser Welding Without Full Melting

Laser welding operates in two primary modes:

Conduction Mode Welding – The laser heats the metal just enough to create a shallow fusion zone. The heat diffuses through conduction, bonding the materials without deep penetration. This is ideal for thin metals or delicate components where excessive heat could cause warping.

Keyhole Mode Welding – Here, the laser’s intensity is high enough to vaporize the metal, creating a deep, narrow cavity (keyhole) that allows for full penetration welds.

The handheld laser welder can switch between these modes based on the application. For instance, when welding jewelry or electronic components, conduction mode ensures precision without damaging sensitive parts.

Why This Matters in Modern Fabrication

Industries are rapidly adopting handheld laser welders because they offer unmatched control and efficiency. Unlike traditional methods, they:

Minimize Heat-Affected Zones (HAZ) – Since the laser’s energy is pinpoint accurate, surrounding areas remain unaffected, preserving structural integrity.

Work on Reflective Metals – With adjustable wavelengths, modern handheld laser welders can even weld challenging materials like copper and aluminum.

Enable Cold Welding Effects – In some cases, the process is so quick and localized that the surrounding metal stays near room temperature, reducing thermal stress.

Applications Where Handheld Laser Welders Shine

From automotive repairs to aerospace manufacturing, handheld laser welders are making waves. Here are some standout uses:

Jewelry Making – Delicate gold and silver pieces can be welded without damaging gemstones.

Medical Devices – Precision welding of surgical tools and implants ensures flawless joins.

Electronics – Circuit boards and micro-components benefit from the laser’s accuracy.

Automotive & Aerospace – High-strength welds on thin sheets reduce weight without compromising durability.

Debunking the Myth: Is It Really ‘No Melt’ Welding?

Technically, some melting occurs, but it’s so minimal that it’s almost negligible. The handheld laser welder’s ability to control penetration depth means the bulk of the material remains solid, unlike arc welding, where the entire joint liquefies. This subtle yet crucial difference makes laser welding a game-changer.

Final Thoughts

The handheld laser welder is more than just a tool—it’s a leap forward in welding technology. By allowing precise, low-heat joins, it opens up possibilities that were once deemed impossible. Whether you’re a craftsman working on intricate designs or an industrial fabricator demanding efficiency, this device is reshaping how we think about metal joining. So, can it weld without melting? Not entirely—but it gets closer than anything else out there!

If you’re ready to experience the future of welding, a handheld laser welder might just be your next must-have tool.