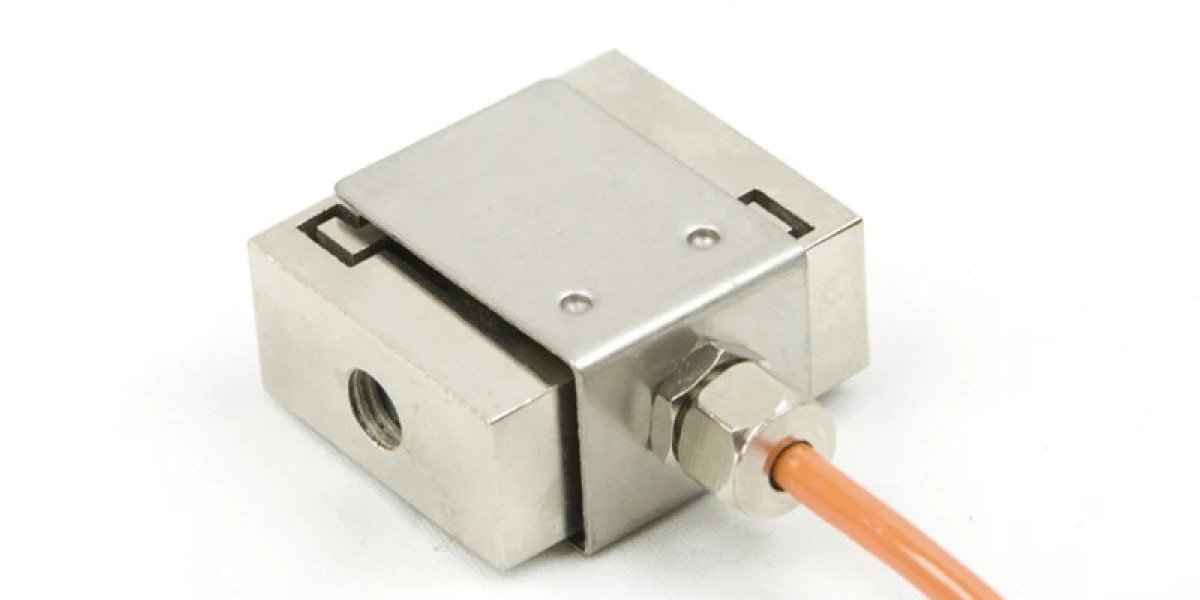

In the evolving landscape of smart manufacturing, one tool is emerging as a true game-changer — the Industrial Robot Automation Tester. Designed for industries seeking optimal performance, higher accuracy, and reduced downtime, this device is rapidly becoming an essential asset in modern automation environments.

What is the Industrial Robot Automation Tester?

At its core, this is an advanced diagnostic and evaluation tool developed to test, calibrate, and verify the performance of robotic systems in industrial settings. Whether it’s assessing robotic arm precision, cycle speed, or motion synchronization, this tester ensures every robot on the floor performs within defined parameters — with little room for error.

Why Your Industry Needs It

In high-output sectors like automotive, electronics, aerospace, and logistics, where robotic arms perform repetitive, high-precision tasks, any deviation from the set calibration can lead to costly defects or production delays. That’s where the Industrial Robot Automation Tester steps in. It streamlines the process of robot health monitoring, helping maintenance teams identify issues before they lead to failures.

Regular testing with this device results in:

Reduced unscheduled maintenance

Extended machine life

Better product consistency

Enhanced worker safety

Key Features That Set It Apart

The latest Industrial Robot Automation Tester is engineered with cutting-edge technology that includes real-time data analytics, wireless integration, and AI-supported diagnostics. Its intuitive user interface allows even non-specialist operators to conduct assessments and interpret results efficiently.

Multi-brand compatibility: It works with major industrial robot brands, eliminating the need for separate testers.

Precision calibration tools: Measure and adjust joint movements down to micrometer accuracy.

Automated reporting: Generate maintenance and performance reports in real time.

Plug-and-play design: Quick installation reduces setup time and boosts testing productivity.

A Cost-Efficient Investment

For many manufacturers, the cost of unscheduled downtime can run into thousands of dollars per minute. By investing in an Industrial Robot Automation Tester, companies can proactively maintain robotic assets and avoid productivity losses. It pays for itself in improved throughput, fewer product recalls, and reduced reliance on manual inspections.

Moreover, as industrial robots become more complex with the integration of AI and machine learning algorithms, having a smart tester ensures you keep pace with technology. This makes it not just a tool for now but a future-ready solution for tomorrow’s automation needs.

Real-World Applications

One leading electronics manufacturer integrated the Industrial Robot Automation Tester across its production lines and reported a 23% improvement in robotic precision and a 38% reduction in unplanned downtimes within the first six months. These real-world benefits highlight the practical value it brings to the table.

Final Thoughts

Automation is no longer a luxury—it’s a necessity. But to harness its full potential, industries must ensure their robotic systems operate at peak performance. The Industrial Robot Automation Tester is more than a device; it’s a performance partner, quality gatekeeper, and a long-term cost saver.