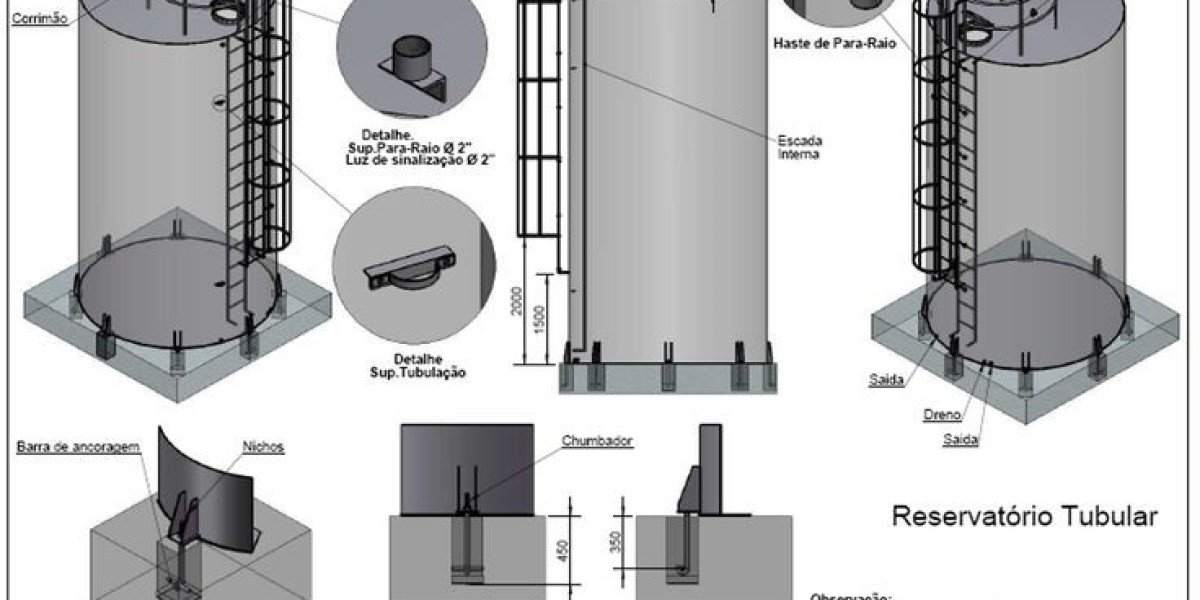

Rainwater Collection Tanks

Available in flat, as nicely as 10 degree to 30 degree roof designs for flat and open J rib or V rib roofs. To find out extra about our tank choices and extra tank appurtenances, speak with certainly one of our tank specialists. Aquamate has been manufacturing galvanized steel water tanks on the market since 1986. Our steel water tanks are engineered in a cutting-edge facility. For our metal water tanks, we use a galvanized tank shell, somewhat than a Zincalume shell, which implies no sacrificial anodes.

There are 12 plates in the column the place, from the bottom-up, there are 4 sieve trays, four ballast trays, and 4 bubble-cap trays. A pump is used to feed the streams into the column and there are pumps on the condenser and reboiler (to overcome head loss). We assume that the condenser is a complete condenser and that the reboiler is whole reboiler. Overall, these components all play a big function in figuring out the effectivity of mass transfer in tray columns.

Water & Petroleum Storage tanks

This permits for the switch of solute molecules from the liquid phase to the vapor part. However, these liquid price pointers are not absolutes as there might be usually significant overlap in the liquid flow rate ranges for various kinds of column internals. In some cases, a mix of trays and packings are utilized in distillation methods depending on the feed nature and composition, and the specified distillate. In general, distillation trays are used for applications with liquid rates of 30 m3/m2-h and above, and/or those the place solids are present or fouling is a priority. Trays are designed to supply liquid holdup (stepwise contact) to realize the correct vapor-liquid mass switch that the distillation course of requires for separation.

Which is Better – Tray Distillation Columns or Packed Columns?

There are several forms of trays utilized in tray columns, including bubble-cap trays, sieve trays, valve trays, and structured packing trays. Bubble-cap trays have a series of raised caps on the tray surface that create small bubbles to promote mixing between the liquid and vapor phases. Sieve trays have a perforated plate with holes that permit the vapor to pass via whereas holding the liquid on the tray floor. Valve trays have movable valves that allow the vapor to cross by way of whereas holding the liquid on the tray surface. Structured packing trays have a specialised packing material that gives a big floor space for mass transfer.

Capabilities

Tray columns provide a quantity of benefits over different kinds of mass switch gear, corresponding to packed columns, including larger capacity, greater efficiency, and decrease strain drop. However, tray columns even have some disadvantages, similar to greater cost, greater complexity, and higher sensitivity to operating situations. Tray stress drops range from 2Vi to 8 mm Hg, relying considerably on I the liquid and vapor loadings, Https://glamorouslengths.com tray kind, ; outlet weir top, and design pres- j sure-drop limitations. Low tray stress drop may find yourself in liquid weeping, whereas operation at a stress drop larger than 8 to 9 mm Hg per tray will often convey on flooding. The liquid level contributes to the tray strain drop even at low vapor flowrates.

Distillation Trays vs. Distillation Packings

Liquid sidedraws are more convenient in trayed columns than in packed columns as a end result of downcomers present a ready place for amassing liquid. Often, the downcomer seal pan is recessed to improve the disengagement of vapor from the liquid. Sidedraw piping must be sized for self-venting and the gravity circulate of saturated liquid, to keep away from flashing within the line. The preliminary horizontal run of gravity sidedraw piping should be freed from valves or different move restriction.

La predisposición de las placas de estructura, el fondo y el techo se lleva a cabo en el nivel superior de soldadura y montaje de la máquina de bobinado. En el curso del proceso de organización, las placas preparadas se ponen en el ubicación de acuerdo con los bocetos gráficos y se fijan con los instrumentos de instalación. Además de su carácter económico, ya que estos depósitos tienen la posibilidad de desempeñar su función hasta con energía solar. Estas bolsas de agua, fabricadas de polietileno indestructible, son la solución idónea para un almacenamiento veloz y simple de agua.

Water towers serve important functions for cities, business, and for individuals who need to improve weather stress from a properly. At the same time, they're feats of engineering and may be extremely costly to build. The value of a sealed small water tower will start from $5,000 but will more doubtless value $10,000-$35,000. On the other hand, metropolis water towers common between $1.7 and $3.8 million. This normally includes a reinforced concrete basis, steel or concrete base, and a metal tank.

Cost To Build Water Tower By Type